Application:

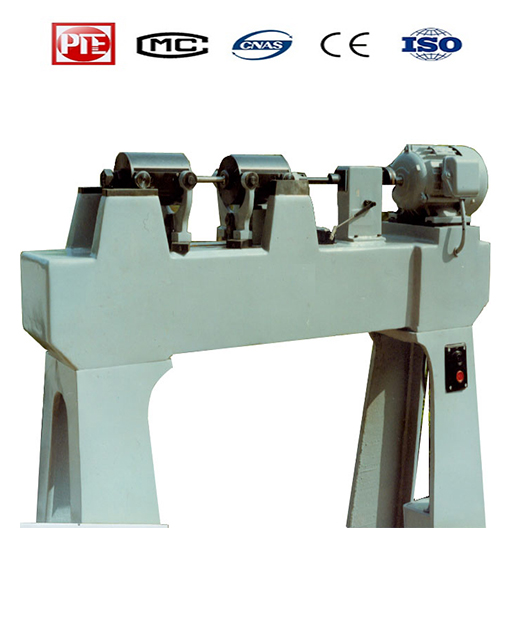

Electromagnetic resonance High-frequency fatigue testing machine has simple structure, convenient operation, high efficiency, low energy consumption and other characteristics, therefore it widely is used in the field of military scientific research, colleges and universities and industrial production.

High-frequency fatigue testing machine is widely used for testing properties of anti-fatigue crack, testing KIC value, S-N curve and so on; it is used for testing fatigue lifetime of all kinds of parts (e.g. plate gear, crank, bolt, chain, connecting rod, compact tension and so on) with various fixtures. It may complete the symmetrical fatigue test, the asymmetrical fatigue test, the unidirectional pulsation fatigue test, the block spectrum fatigue test, the modulation fatigue test, the fatigue test at high and low temperature, three point bending, four point bending, torsion fatigue tests and so on. At present colleges and universities, research department and industrial and mining enterprises use the high frequency testing machine to carry on fracture toughness test and testing metallic material crack growth rate and limited value of martial. With the development of microelectronic technology and computer technology, as well as perfect test method, its use function is increasing expansion.

This machine undergoes optimization design and the structure is rational. The automatically controlled system adopts the advanced pulse wide control system and new-type power amplifier to improve the reliability of the electric system

Specifications:

Model | PLG-10C | PLG-20C | PLG-50C | PLG-100C | PLG-200C | PLG-300C | |

Mean load max(kN) | ±10 | ±20 | ±50 | ±100 | ±200 | ±300 | |

Force amplitude(kN) | ±10 | ±10 | ±10 | ±50 | ±100 | ±150 | |

Load step | 1,2,5 | 1,2,5 | 1,2,5 | 1,2,5 | 1,2,5, | 1,2,5 | |

Accuracy of static load | ≤±1% | ||||||

Range of frequency(Hz) | 60~300HZ | ||||||

Power | 380V, 3phs, | ||||||

Load fluctuation | Dynamic | 0.5%F-S | |||||

Static | 0.5%F-S | ||||||

Max. distance between grips (mm) | 600 | 600 | 600 | 800 | 800 | 800 | |

Max. distance between columns (mm) | 400 | 420 | 480 | 500 | 540 | 620 | |

Dimension (mm) | Main unit | 680×500 | 700×500 | 800×700 | 900×800 | 1100×1100 | |

Electric controller case | 600×650×1200

| ||||||

weight (kg) | Main unit | 1300 | 1500 | 1500 | 2750 | 4000 | 7200 |

Electric controller case | 50 | 50 | 70 | 70 | 100 | 120 | |

PLS Series Dynamic and Static Electro- Hydraulic Servo Testi

PLS Series Dynamic and Static Electro- Hydraulic Servo Testi  Model PQ-6 Pure Bending Fatigue Testing Machine

Model PQ-6 Pure Bending Fatigue Testing Machine  Model PFT Series Screen Display Hydraulic Impulse Fatigue Te

Model PFT Series Screen Display Hydraulic Impulse Fatigue Te