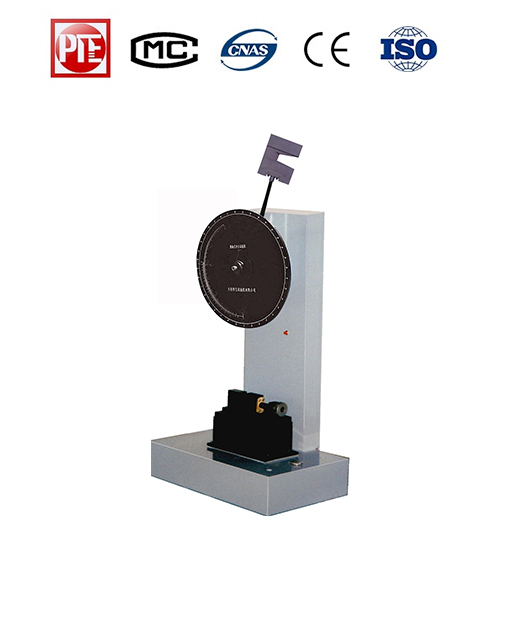

Applications:

It is mainly used in testing the nonmetal materials' impact toughness, such as horniness plastic, strong nylon, glass reinforced plastics, china, clay rock, anti-electric and metal materials. It can do both Charpy, Izod and tensile impact test as the standards of ASTM D 256-90 Meth. A, ASTM D 256-90 Meth.B, ASTM D 256-97, ASTM D 6110-97, ASTM D 5942-96 ASTM D 1822, ASTM D 4812, DIN 53753, DIN 53453, DIN 51222, DIN 53448, ISO 180, ISO 179, ISO 8256, BS 2782 Part.3 Meth. 350, BS 2782 Part. 3 Meth. 359. BS 7413, AFNOR T51-111, UNI 6323, UNI 6062, GB/T1043、GB1843.

Each type has both electronic type and pointer type. The electronic type adopts raster -display technique of measuring circle angle, with the characteristics of high precision, good stability and wide range of measuring, digital display of testing split strength, impact intensity, fore-elevation, ascending angle, automatic correcting average value of one group for energy losing.

Main technical parameter:

Distance between clamps of Charpy: 40mm 60mm 70mm 95mm

(Izod) Impact energy: 1J 2.75J 5.5J 11J 22J impact speed: 3.5m/s

(Charpy)Impact energy: 1J, 2J, 4J, 5J, 7.5J, 15J, 25J impact speed: 2.9m/s and 3.8m/s

(Tensile Impact Test) Impact energy: Capacity: 5, 15J Impact velocity: 2.9/3.8m/s

Main configuration

1. Main frame one

2. Cantalever girder grip one

3. Fastness support seat(on charpy impact grip) one

4. Movement support seat(on charpy impact grip) one

5. Former for regulate center( 40,60,70,95) one set

6. Adjustment gasket(2 ,2.5,3.5, 5,7 ) two each

7. R1 R2 supporting knife-edge two each

8. Cantilever girder benchmark one

9. Charpy impact hammer(1J 4J 7.5J 15J 25J ) one each

10. Cantalever girder hammer(1J 5.5J 11J 22J ) one each

11. Charpy impact weight(2J 5J) one each

12. Cantalever girder weight (2.75J) one

13. Tensile Impact hammer (3J, 15J) one each

14. Power line one

15. Internal six angle spanner(4、5、6、8) one each

16. Screwdriver one

Model XJB-3 Film Impact Tester

Model XJB-3 Film Impact Tester  Dichloromethane soak testing machine

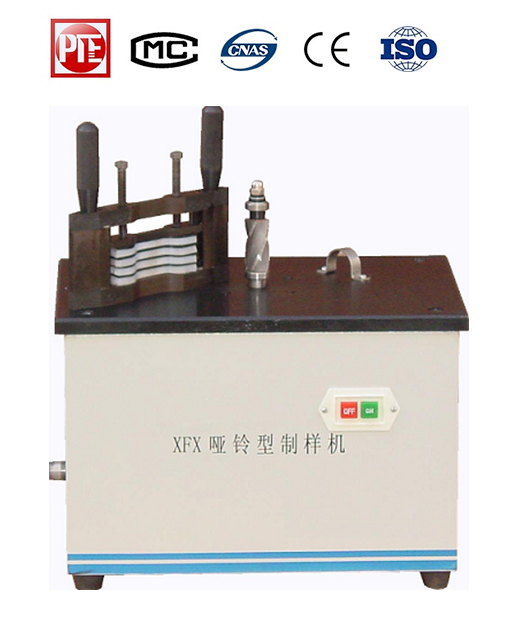

Dichloromethane soak testing machine  XFX Dumb-bell sample-making machine

XFX Dumb-bell sample-making machine  XBM-100 apparent density tester

XBM-100 apparent density tester