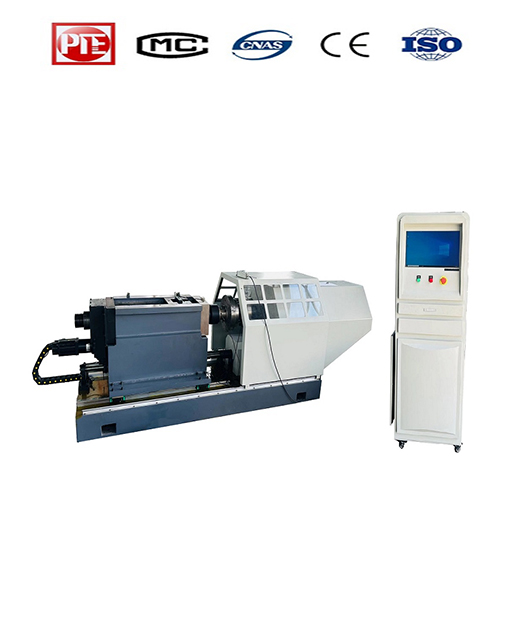

Main application and technical parameters:

Main application

This detector is designed and manufactured in accordance with the requirements of NB/T31082-2016 "High strength bolt connection pairs for wind turbine tower" DL/T284 "Hot dip galvanized bolts and nuts for transmission line towers and power fittings" GB/T3098.1-2010 "Mechanical properties of fasteners - bolts, screws and studs" GB50205-2001 "Acceptance code for steel structure engineering". It can detect, display and print the axial force, torque, and torque coefficient of high-strength bolt connection pairs (M33-M64) with large hexagonal heads. When the axial force reaches the standard value, the detector emits a buzzing sound and records the peak value of the detection data. After the device stays for 1 second, it automatically reverses and releases the sample. At the same time, the detector automatically calculates the torque coefficient based on the detected axial force and torque and displays it automatically; After a set of experiments is completed, the detector automatically calculates the average axial force, average torque, average torque coefficient, standard deviation, and coefficient of variation of N specimens; After equipped with a torsion shear wrench, the pre tightening force of the torsion shear bolt can also be checked. This equipment is mainly used for the detection of steel structures and large wind power bolts

Technical Parameter:

1. Voltage: Control system 220V AC; Motor AC 380V

2. Servo motor power: 5.0KW, traction motor 250W

3. Output speed: about 1r/min

4. Axial force detection range: 100-2000kN

5. Torque detection range: 500-30000Nm

6. Bolt specification: M33-M64

7. Bolt length: 120m --500m

8. Test accuracy: axial force ± 1.0% torque ± 1.0%

9. Display of axial force, torque, time and other curves

10. External dimensions (length * width * height): 3500 * 1200 * 1250

11. The total weight of the equipment is approximately 8000kg

Main configuration:

Sno | Name | Unit | Qty |

1 | Test host (including 2000kN axial force sensor and 30000NM torque sensor) | set | 1 |

2 | Panasonic servo motor 5.0kN and Panasonic dedicated servo controller | set | 1 |

3 | Measurement and control system of microcomputer controlled high-strength bolt special testing machine | set | 1 |

4 | Carrying base electric front and rear drive system | set | 1 |

5 | Specific servo electric drive system for sample clamping sliding clip | set | 1 |

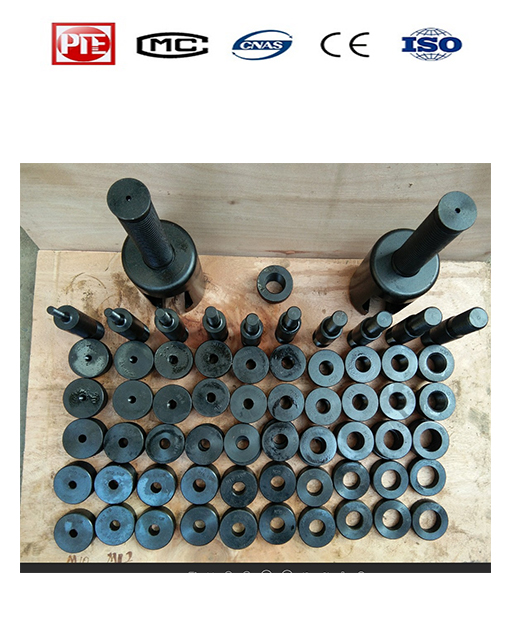

6 | Bolt installation accessories: M33/36/39/42/45/48/52/56/64 | set | 1 |

7 | Lenovo Computer's Current Mainstream Configuration Host and 19 inch LCD Display | set | 1 |

8 | Laser printer | set | 1 |

9 | Fully enclosed and transparent sliding safety protection device | set | 1 |

Bolts and Nuts Test Accessories

Bolts and Nuts Test Accessories  Model BT Series (1000-7000kN) Computer Control Bolt Tensile

Model BT Series (1000-7000kN) Computer Control Bolt Tensile  Model YJZ-2500E Computer Control High-strength Bolt Tester

Model YJZ-2500E Computer Control High-strength Bolt Tester