Main Applications:

The high-strength bolt test fixture is carefully designed and manufactured by our company according to the relevant national standards GB/T3098.1-2000, using special materials. Through different combinations, it can be used for bolt wedge load test, ordinary tensile test, bolt minimum tensile load test, and nut guaranteed load test. This fixture is clamped into the jaws of the universal testing machine by connecting rods, allowing for various tensile tests. Ordinary hydraulic universal testing machines do not require the addition or modification of other devices.

Main technical indicators:

1. Maximum tensile force of wedge load test: 696kN (M30-10.9s)

2. Minimum tensile load test for bolts: 583kN (M30-10.9s)

3. Nut guarantee load test: 583kN (M30-10.9)

4. Bolt guarantee load test: 466kN (M30-10.9s)

Note: High strength bolt test fixtures above M30 require special ordering

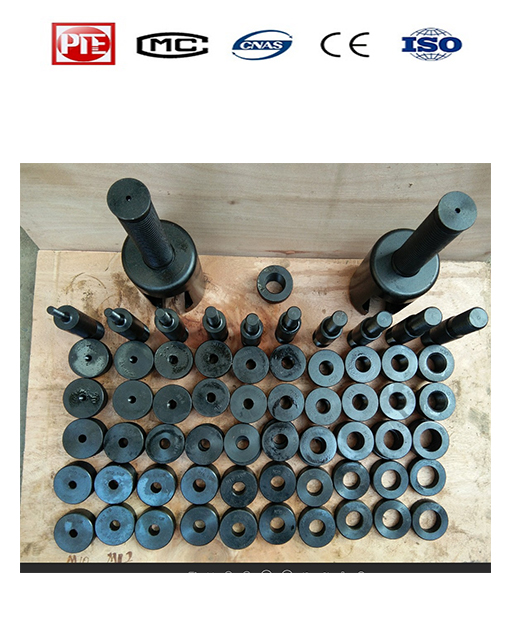

Fixture configuration:

1. Clamp specific (including pull rod) one pair (a total of 4 pieces)

2. One flat washer M10, M12, M14, M16, M18, M20, M22, M24, M27, and M30 each (a total of 10 pieces)

3. Two tension rings with internal threads, M10 \ M12 \ M14 \ M16 \ M18 \ M20 \ M22 \ M24 \ M27 \ M30 each (a total of 20 pieces)

4. Wedge load blocks M10, M12, M14, M16, M18, M20, M22, M24, M27, and M30 each, one pair (2 pieces/pair, a total of 20 pieces), with 10 º and 6 º for M20 and below

M22 (including M22) and above are 4 º and 6 º

5. Nut test core rod M10 \ M12 \ M14 \ M16 \ M18 \ M20 \ M22 \ M24 \ M27 \ M3, one piece each, and an additional M33 universal tensile ring for the core rod (a total of 10 pieces)

(A total of 65 sets of fixtures)

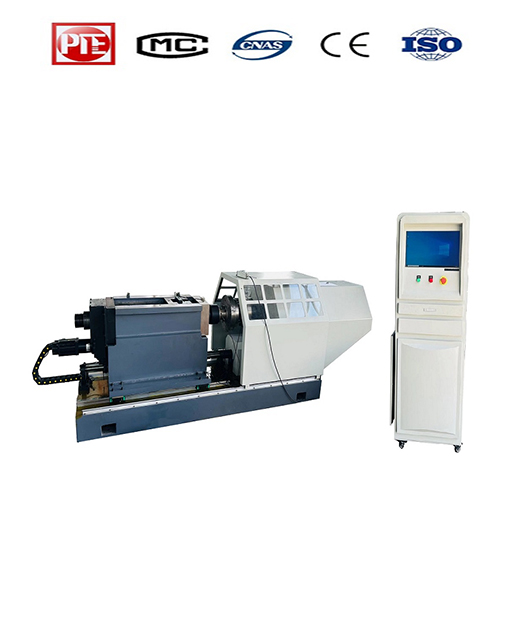

Model BT Series (1000-7000kN) Computer Control Bolt Tensile

Model BT Series (1000-7000kN) Computer Control Bolt Tensile  Model YJZ-2500E Computer Control High-strength Bolt Tester

Model YJZ-2500E Computer Control High-strength Bolt Tester  Model YJZ-2000E Computer Control High-strength Bolt Tester

Model YJZ-2000E Computer Control High-strength Bolt Tester